SOLAR WATER DISTILLATION FACT SHEET

What is Solar Water Distillation?

There is a great need to find ways to supply water for the Earth’s population. Many countries are facing water shortages and/or have residents who use and drink contaminated water. Finding different ways to use our renewable resources (for example, solar power) has become an interest. Solar water distillation is the process of using energy from the sunlight to separate freshwater from salts or other contaminants. The untreated water absorbs heat, slowly reaching high temperatures. The heat causes the water to evaporate, cool, and condense into vapour, leaving the contaminants behind. Solar stills can be used for low capacity and self-reliant water supplying systems.

How it Works

Solar water distillers or solar stills are usually used in remote areas where there is limited access to freshwater. The basic principles of solar water distillation are simple, yet effective, as distillation replicates the way nature makes rain. A solar still works on two scientific principles: evaporation and condensation. The salts and minerals do not evaporate with the water. For example, table salt does not turn into vapour until it gets to a temperature over 1400ºC. However, it still does take a certain amount of energy for water to turn into water vapour. While a certain amount of energy is needed to raise the temperature of a kilogram of water from 0ºC to 100ºC, it takes five and one-half times that much to change it from water at 100ºC to water vapour at 100ºC. Practically all this energy, however, is given back when the water vapour condenses.

Most stills are simple black bottomed vessels filled with water and topped with clear glass or plastic. Sunlight that is absorbed by the black material speeds the rate of evaporation. The evaporation is then trapped by the clear topping and funneled away. Most pollutants do not evaporate, so they are left behind. Most stills need to be about six square meters in size to produce enough water for a single person for a day. Multiple solar distillation systems are required to produce a large quantity of distilled water.

Advantages:

It is a relatively cheap and low-maintenance system.

It can be used at the household level and scaled up through programmatic approaches.

There are climate change adaptation and mitigation benefits.

There are no energy costs.

There are no moving parts.

Disadvantages:

Rate of distillation is usually very slow (6 litres of water per sunny day).

It is not suitable for larger consumptive needs.

The materials required for the distiller may be difficult to obtain in some areas.

If not correctly disposed of, the distillation process waste stream can be a potential source of environmental pollution (high concentrations of salts and pollutants).

Solar energy is only available during the day.

Types of Solar Water Distillers

Solar distillation systems can be classified as passive and active. Solar radiation is the input energy of the passive solar stills, but the efficiency of the system is low. Attempts have been made to increase the efficiency and productivity by preheating the saline water in solar stills. This method is called active solar distillation. In the case of active solar distillation, an additional source of thermal energy is required for faster evaporation inside the same passive solar still. The additional source may be a solar-energy-based system or thermal energy contained in hot water which is discharged by other industries. There are many different ways to make a solar still and different materials that can be used. A crucial design challenge is making sure that the stills are airtight. If they are not airtight, efficiency drops severely. Listed are the different types of passive solar water distillers.

Single-effect Stills: These are the most common and simplest stills. Only one interface is necessary to convey the energy and collect the condensate.

Multi-effect Stills: They require double the effort in regards to ensuring tight seals and can be more difficult to clean, but they can significantly increase the production of distilled water.

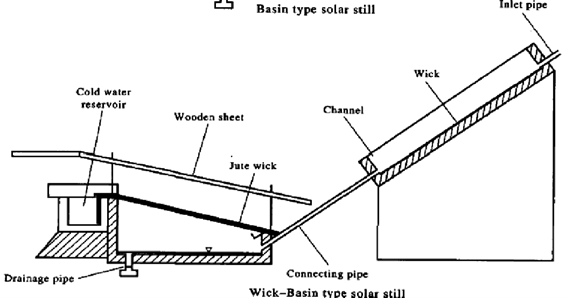

Basin-type Stills: They contain the water in an impervious material that is a component of the entire enclosure and these are the most common type.

Wick Stills: Use cloth-like materials that use capillary action to propagate the water through the system.

Multi-wick Stills: These stills, like wick and multi-effect stills, greatly increase the productivity by increasing the influenced surface area exponentially.

Diffusion Stills: They use the ideas introduced by the multi-effect and wick stills and are a further advancement of both. They consist of a series of closely space parallel partitions in contact with saline-soaked wicks and they have great potential because of their high productivity and simplicity.

Different stills require different materials, some have simple materials and other stills can have more sophisticated materials. Here is an example of a type of wick still and the details regarding how it works.

The solar radiation falling on the glass cover is transmitted to the wick surface. A portion of the energy is used for heating the water flowing through the wick due to capillary action.

The heat transfers in the distillation system are governed by external and internal modes. The external heat transfer mode occurs due to convection and radiation, which are independent from each other and occur outside the still. The heat transfer within the solar distillation unit is referred to as the internal heat transfer mode, which occurs due to radiation, convection, and evaporation. In internal heat transfer mode, the mass transfer is accompanied by radiation and convective heat. Water flowing through the wick surface gets heated and evaporated into vapour. The saturated vapour condenses in the lower surface of the glass cover after releasing the latent heat of vapourization. The condensed water droplets trickle down due to gravity and are collected in the drainage channel. The more wicks, the more heat can be transferred to the salt water and more product can be made. A plastic net can also catch salt water before it falls into the container and give it more time to heat up and separate into brine and water. Glass’ absorption of heat is negligible compared to that of plastic at higher temperatures.

The main part of the still is the basin, this is where the water you are going to distill is poured. Side walls are what give the still structure. The material used should be able to resist heat transfer to the area surrounding the still. The more heat trapped, the more efficient the water system. It should also be able to support the cover and prevent the water from spilling. The top cover is what is used to collect the condensed vapour from the distillation process, and the only way for heat to get into the still. The cover should be transparent, resistant to water absorption, easily cleaned, and very smooth. The distilled water is collected into a trough or passage, which then trickles out into a channel.

Distilled water from a solar water distiller can be used for washing clothes and bathing, cooking, and emergencies. For it to be safe to drink, softened water or salt water should be used.

Was this information useful? If so please help us to continue to educate the leaders of today and tomorrow! Please chip in $5 or donate $20 or more and receive an Official Donation Receipt for Income Tax Purposes.

Resources

All About Water Filters. (2018). Ultimate Guide to Solar Water Distillers: Solar Water Distillation 101. Retrieved from http://all-about-water-filters.com/ultimate-guide-to-solar-water-distillation/

Appropedia. (2017, Nov. 9). Solar Distillation. Retrieved from http://www.appropedia.org/Solar_distillation

Climate Technology Centre & Network. (n.d.). Solar water distillation. Retrieved from https://www.ctc-n.org/technologies/solar-water-distillation

Ranjan, K. R. Kaushik, S. C. (2013, Jun. 19). Economic feasibility evaluation of solar distillation systems based on the equivalent cost of environmental degradation and high-grade energy savings. Retrieved from https://academic.oup.com/ijlct/article/11/1/8/2363380